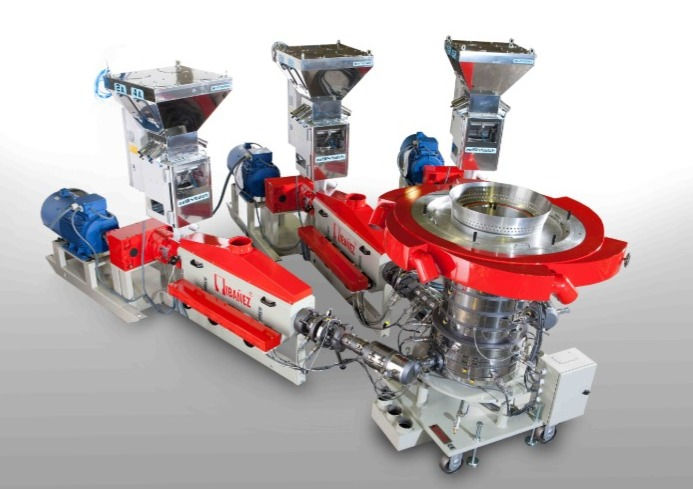

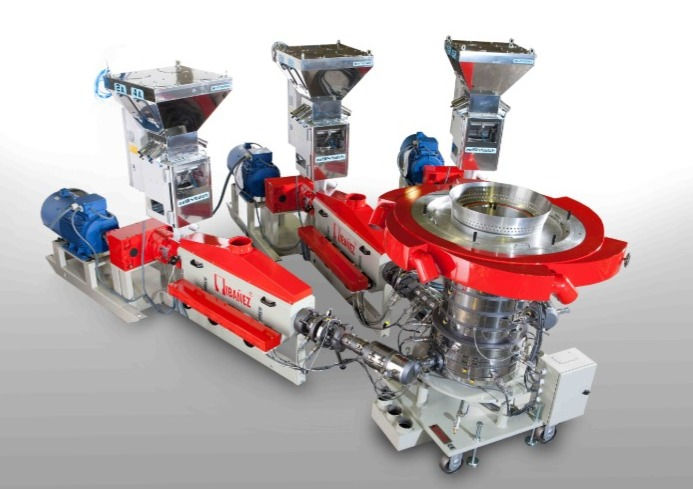

MULTILAYER

CONTROL DEVICES:

-

Control of the weight of the material in g/m and dose in % of each of the components.

-

Manual and hydraulic screen changers.

-

Automatic thickness control placed on the air cooling ring

-

Film width and thickness meter devices.

-

Automatic guiding-band.

-

Web tension control through load cells.

-

Internal bubble cooling systems with width control via ultrasound sensors.

-

Automatic sheet cutting with bar feeder and hydraulic discharge coil.

-

Fully automatic winding station with bars feeder and hydraulic reels unloading system

-

The entire line is controlled by a PLC with field buses Device net and Ethernet

-

Remote supervision via internet and SCADA programme, running in an industrial fan-less PC with touch screen 15 / 17", 320 GB HHD.

-

Static electricity dischargers.

Completely personalized multilayer installations with all the possible controls to make co-extrusion an art.

High production capacity and high quality is what you obtain with our machines for whatever material composition and application that you may need to use.

Widths of up to 2500mm.

Co extrusion blown film line